Cleaning swabs are indispensable tools across various industries, ensuring the pristine condition of delicate equipment and surfaces. Whether in cleanrooms, electronics, or medical settings, the right cleaning swab is essential for maintaining optimal performance and longevity. In this comprehensive guide, we'll explore the types, materials, and applications of cleaning swabs, with a special focus on IPAswab, a revolutionary product that stands out in the cleaning industry.

Types of Cleaning Swabs

Based on Head Material

- Cotton Swabs: Cost-effective and absorbent, but may leave fibers.

- Foam Swabs: Low-linting and non-abrasive, ideal for delicate surfaces.

- Polyester Swabs: Durable and low-lint, perfect for cleanrooms and electronics.

- Microfiber Swabs: Excellent particle pick-up and non-abrasive.

- Rayon Swabs: Highly absorbent, used in medical and laboratory settings.

Based on Handle Material

- Wooden Handle Swabs: Sturdy and economical.

- Plastic Handle Swabs: Flexible and suitable for sterilization.

- Metal Handle Swabs: Durable and strong for specialized applications.

Based on Head Shape and Size

- Round Tip Swabs: Versatile for general cleaning.

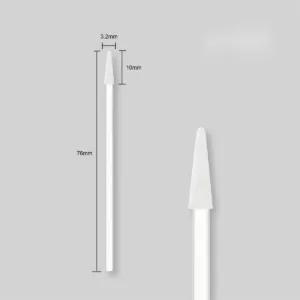

- Pointed Tip Swabs: Precision cleaning in hard-to-reach areas.

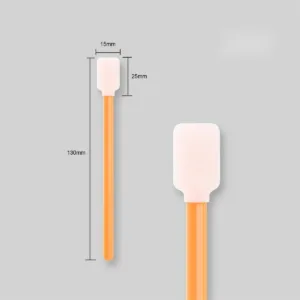

- Paddle Tip Swabs: Larger surface area for extensive cleaning.

- Sponge Tip Swabs: High absorbency and gentle cleaning.

- Specialty Shapes: Angled and curved swabs for specific needs.

Based on Features

- Sterile Swabs: Suitable for medical and pharmaceutical environments.

- Static Control (ESD) Swabs: Crucial in electronics manufacturing.

- Pre-saturated Swabs: Conveniently pre-wetted with cleaning solutions like IPA.

Materials Used in Cleaning Swabs

Head Materials

- Cotton: High absorbency but may shed lint.

- Foam (Polyurethane, Polyester): Low lint and good solvent resistance.

- Polyester: Low linting and chemical resistance.

- Microfiber (Nylon, Polyester blends): Excellent at trapping particles.

- Rayon: Highly absorbent, used in medical applications.

Handle Materials

- Wood (Birch, Poplar): Rigid and cost-effective.

- Plastic (Polypropylene, ABS): Flexible and chemical-resistant.

- Metal (Stainless Steel, Aluminum): Durable for industrial settings.

Applications of Cleaning Swabs

Cleaning swabs are used in various industries, including:

- Medical and Healthcare: Wound cleaning, specimen collection.

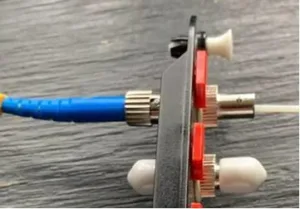

- Electronics Manufacturing: Removing solder flux, static control.

- Aerospace and Automotive: Precision cleaning of components.

- Pharmaceutical and Biotechnology: Equipment maintenance, sterile sampling.

- Optics and Photonics: Cleaning delicate lenses.

- Cosmetics and Personal Care: Applying makeup, skincare products.

- Industrial Maintenance: Cleaning machinery, hard-to-reach areas.

- Arts and Crafts: Applying glues, paints.

Introducing IPAswab

IPAswab is a pre-saturated cleaning swab specifically designed for critical cleaning tasks. It is pre-wetted with high-purity isopropyl alcohol (IPA), making it ideal for removing contaminants from sensitive surfaces without leaving residue.

Benefits of IPAswab

- High Purity IPA: Ensures effective cleaning without introducing new contaminants.

- Convenience: Ready to use, saving time and effort.

- Versatility: Suitable for electronics, medical devices, and cleanrooms.

- Low-Linting Materials: Minimizes particle release, crucial for sensitive environments.

How to Choose the Right Cleaning Swab

When selecting a cleaning swab, consider:

- The surface or component to be cleaned.

- The type of contaminant to remove.

- Required cleanliness level and sterility.

- Solvent resistance and antistatic properties.

- Accessibility of the area to be cleaned.

- Budget and quantity needed.

Best Practices for Using Cleaning Swabs

- Use a fresh swab for each task to prevent contamination.

- Apply gentle, controlled pressure appropriate for the surface.

- Ensure even saturation without dripping when applying liquids.

- Dispose of used swabs responsibly, especially in medical settings.

- Store swabs in a clean, dry place to maintain integrity.

Conclusion

Cleaning swabs are vital tools for maintaining cleanliness and the integrity of sensitive equipment and environments. By understanding the various types of swabs available, the materials they are made from, and their specific applications, you can make informed decisions to select the most appropriate swab for your unique needs.

IPAswab offers a convenient and effective solution for critical cleaning tasks, ensuring optimal performance and longevity of your valuable equipment. Explore the benefits of IPAswab today and elevate your cleaning practices to new heights.

Explore more about IPAswab and other cleaning solutions at [hxswab.com](http://hxswab.com "hxswab.com")!