To clean dust from the gaps in an SNSPD (Superconducting Nanowire Single-Photon Detector) fiber connector, follow these steps carefully:

1. Use an Air Blower

- Use a manual air blower (bulb blower) to gently blow away dust from the fiber connector gaps. Ensure the air blower is clean and free from contaminants.

- Avoid compressed air cans, as they may release moisture or chemical residues, which could damage the sensitive surfaces.

2. Fiber Cleaning Stick

- Use a fiber optic cleaning stick designed to reach into small gaps. Insert the stick gently into the fiber connector and rotate it to dislodge and remove dust or debris.

- These sticks are often made from soft materials that won't scratch or damage the fiber connector.

3. Lint-Free Wipes and Isopropyl Alcohol (IPA)

- For more stubborn contaminants, use lint-free wipes or a fiber cleaning stick moistened with high-purity isopropyl alcohol (IPA) (usually 99% or above). Lightly wipe the connector area and allow the alcohol to evaporate.

- Ensure the IPA is of high purity to avoid leaving any residues.

4. Dry Cleaning Methods

- Dry fiber cleaning pens are another effective tool for cleaning fiber connectors. Insert the pen into the fiber connector port and twist it to clean the inner surfaces without using any solvents.

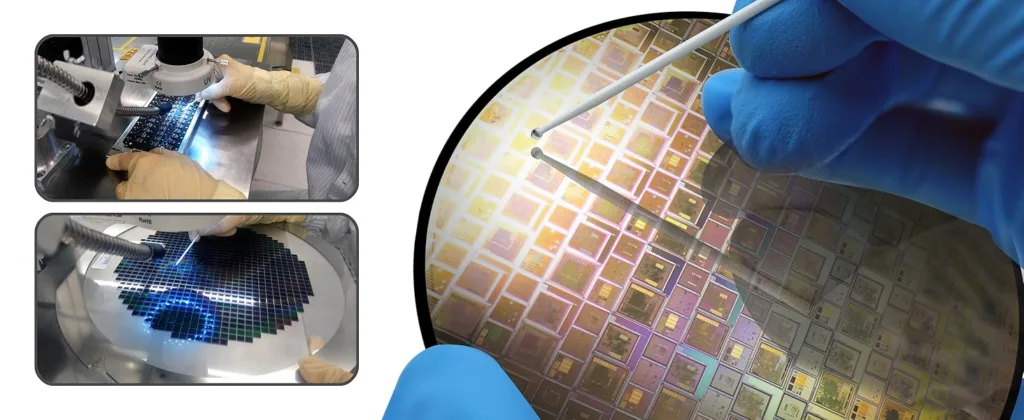

5. Microscopic Inspection

- After cleaning, use a fiber optic inspection microscope to check the cleanliness of the fiber end face and connector gaps. This ensures no dust or debris remains, which could affect signal transmission.

6. Work in a Clean Environment

- Perform the cleaning in a controlled, dust-free environment (e.g., cleanroom or workstation) to avoid further contamination during the cleaning process.

Following these steps will help ensure effective removal of dust from SNSPD fiber connector gaps, protecting the performance and longevity of the device.

Suzhou Hongxun Dustless Technology Co., Ltd. designed and developed the sticking stick to solve this problem perfectly.

Applications

- It has good adsorptivity. It mainly cleans the micro dust ions on the bare sensor surface by cob process. Compared with the ordinary cotton swab (wiping the surface glass of cspensor with clean water), it does not produce dust spots, scratch sensor and leave stains, which can greatly improve the yield of the product.

- Clean the surface of LED / LCD (10-5000 clean room).

- Clean debris and dust from lens surface glass.

- Cleaning the watch parts

- Cleaning the specular microscope

- Cleaning the sensor of the camera

- Cleaning the hard disk driver

- Cleaning precision instruments

- Cleaning small areas

- Removing excess materials

https://hxswab.com/product-category/clean-swabs/gel-sticky-swab-clean-swabs